Q-upAuto

Monitor and Better Understand your Inspection Data to Improve 100% Productivity

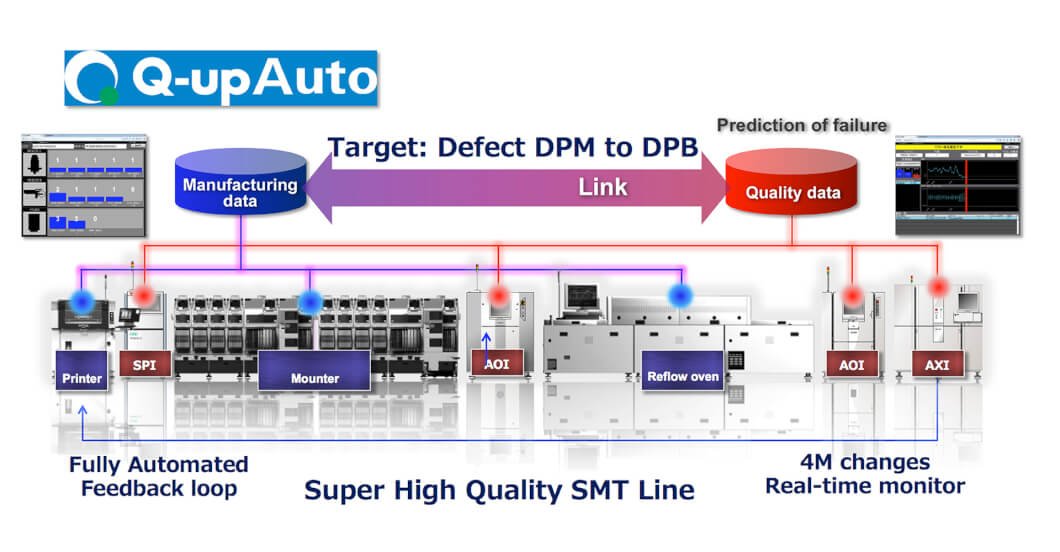

Q-upAuto System for executing association, collection, monitoring and improvement of each facility data, using the quality information of OMRON inspection system as a starting point.

How can we help you?

If you have a question, please contact us or send a request.

Contact me Q-upAuto

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

Download

Omron Q-upAuto:

Advanced Manufacturing Analysis Combining Q-upNavi Inspection Result Data, with Manufacturing Process Data for High Level Process Improvement.

Presenting new Values by linking Inspection and Mounting systems

Detection and correction of mounter-originated sudden defect causes

Mounter-related defects are detected and notified instantly. Pinpoint identification of research target is possible, thanks to listed defect component and mounting information. Detection of Mounter defect is correlating to each nozzle, head and reel, within all CAD locations from both pre and post reflow AOI systems. As a result, line stop time can be reduced, contributing to productivity improvement.

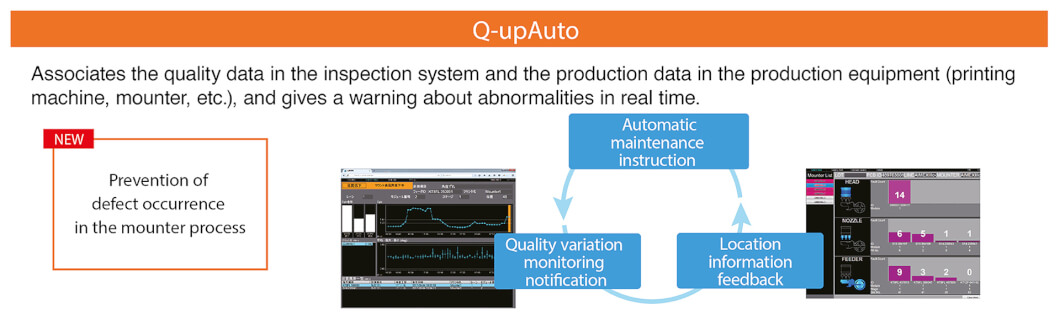

Defect prevention

The system outputs notification when detecting mounter-related quality degradation such as component mounting shift variations. Effective not only to prevent defects, but also to know the timing for mounter machine maintenance and required part replacement.

Checking improvement result on mounter

Checking defect correction result or post-correction quality deterioration is possible by collecting mounter-related correction information and comparing auto-saved pre- and post-correction results. Easy verification and visualization of correction operation and its effects are possible.

Videos

-

Q-up System Inspection

Q-upAuto System for executing association, collection, monitoring and improvement of each facility data, using the quality information of OMRON inspection system as a starting point.

01:19