VT-S1040

3D PCB Optical Inspection System

The VT-S1040 is the world’s most advanced 3D AOI system, designed for the high-quality manufacturing market. New technologies to overcome the shortfall in production yields traditionally caused by shadow, reflection and cycle-time to realize unmanned inspection process in combination with labor-saving maintenance, using predictive maintenance.

- Fastest cycle-times with high performance 25Mpix Camera.

- Industry-first MDMC Illumination: 3D imaging from all angles enables accurate inspection of complicated solder shapes.

- Elimination of Shadow and Secondary Reflection with 4-Direction MPS Projectors

- First Pass Yield efficiency up to 99%.

- Complete Offline Program Generation without Interrupting Production.

- Unique AI for Skill-less labor-saving Program Optimization.

- Unique Global Library to maintain same quality standard across all Production Lines.

- Unique Connection to: Omron Q-upNavi: Combine Omron SPI, AOI and AXI Result Data Together for True Root-Cause Analysis.

- Unique Connection to: Omron Q-upOpti: Skill-less SPI Setting and Optimisation calculated from AOI Solder Values.

- Unique Connection to: Omron Qup Auto-I: Production Quality Analysis across your Entire Production Line.

- Unique Connection to Omon Qup Auto-C: maintains high quality and high productivity autonomously in your production line.

How can we help you?

If you have a question, please contact us or send a request.

Contact me VT-S1040

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadFeatures

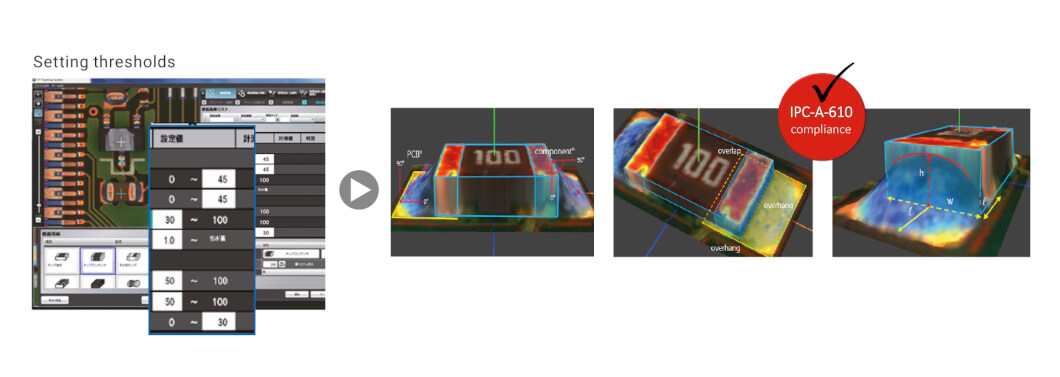

AI-assisted qualitative inspection conforming to international standards

Since values conforming to the standards are directly applied as inspection criteria, there is no dependency on the skill and expertise of the programmer.

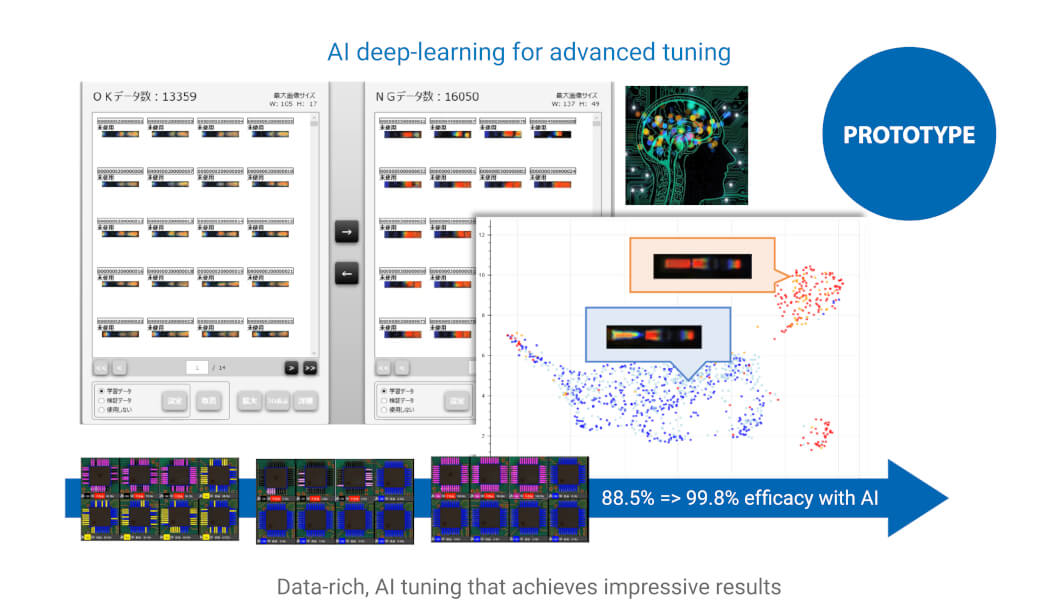

AI technology to minimize programming and visual inspection efforts

1. AI self-optimization

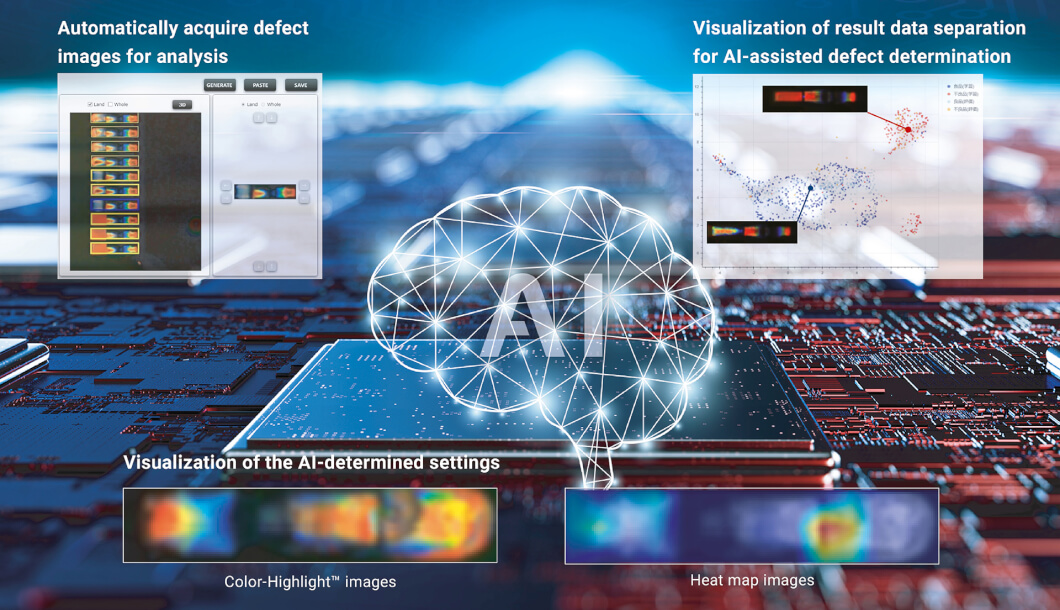

2. Automatically acquire defect images for analysis and visualization of result data separation for AI-assisted defect determination

3. Visualization of the AI-determined settings

High-precision solder shape reconstruction

Equipped with our unique MDMC (Multi Direction/Multi Color) illumination and new patented MPS (Micro Phase Shift) Moiré Technique. This enables higher robust and reliable inspection performance.

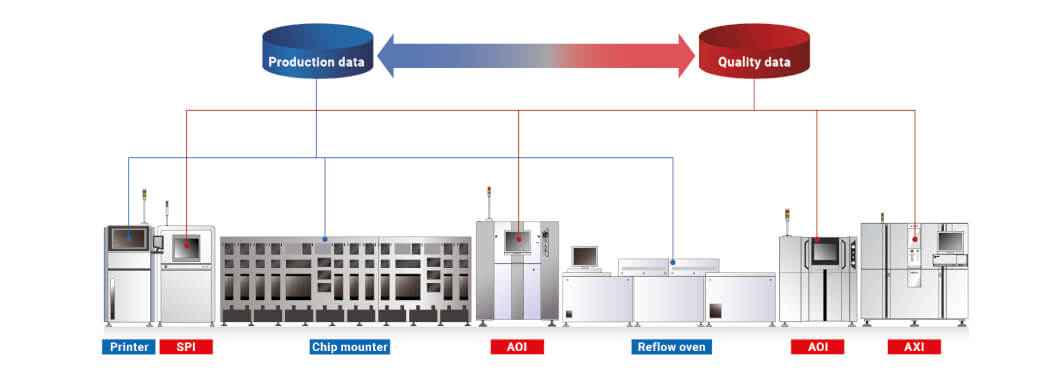

M2M*1 system focusing on quality

1. Preventing defects by:

- monitoring and reporting fluctuations in the measured values during production

- visualizing defect trends associated with chip mounter hardware such as heads and nozzles

2. Visualizing the quality by:

- process comparison

- displaying production status

- linking SPI/AOI/AXI systems

3. Improving the first pass yield rate of the line by automatically calculating post-print/post-placement inspection criteria based on the inspection results after the solder reflow process

*1. Abbreviation of machine-to-machine. It is a mechanism to optimize the quality and equipment operation status without human intervention, made possible by enabling autonomous communication and exchange of information between various connected, production equipment.